Source: Dover's

Environmental Solutions Group With most fleet owners, when the topic of fleet management comes up, the notion of maintenance schedules, vehicle metrics and up-time statistics probably comes to mind. Fuel usage, annual maintenance spend and replacement schedules are additional bits of information that assist fleet owners in ensuring their fleets are operating profitably. But in today’s business environment, where a digital presence is everywhere – including the telematics generated by most class 8 chassis, the stream of information is invaluable – but only if you have the ability to understand and process that language. Knowing where your vehicles are is one thing, but knowing if they’re operating at peak performance – while at the same time monitoring your operators and their environments simultaneously – is something completely different. You need a strategy to collect the data – and then act upon it. Welcome to the Internet of Possible.

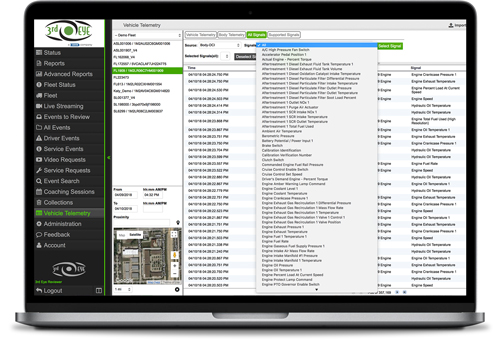

The ProblemThe potential of interpreting the chassis and body telematics into useful reports was the challenge that intrigued 3rd Eye engineers a few years back. They understood the information provided by engine manufacturers, like Cummins – who captured and transmitted engine data based on sensors connected to the J-1939 bus, would be so much more valuable if it could be combined with telemetry generated by a vocational body’s sensored systems. The stream of both chassis and body data could potentially provide fleet owners with a new way of gauging the health of their fleet – while also delivering a more granular look at overall fleet management. It would present a paradigm shift in how fleets gauged productivity and profit. The key to the whole mix would revolve around blending and transforming these streams into relevant courses of action.

Another equally daunting challenge was managing the other data collecting systems in the cab, including cameras, monitors, and under-dash dongles that tracked the vehicle’s location, speed, and surroundings. These systems were also deemed necessary, but in-cab real estate was at a premium, not to mention the added expense of the multiple cellular connections often needed to communicate with backroom route monitoring software.

The Opportunities

In the case of today’s garbage trucks, route management is at the heart of fleet management. Optimizing the right collection vehicle with the route that maximizes manpower and vehicle efficiencies is key to profitability. And likewise, being alerted to an anomaly before it becomes critical can be the difference between routine maintenance and a costly ‘truck down’ situation. It’s also critical [or should be] for fleet owners in 15 states to know when their vehicles are operating on federal highways or off – and when fuel is being consumed for purposes other than propulsion. The fuel tax allocated for this application is refundable. For fleets that operate hundreds – or thousands of vehicles, this can mean millions in annual tax rebates.

3rd Eye – one of the pioneers of onboard vehicle safety cameras and collision-avoidance Doppler radar, developed the Hurricane™ Gateway – which allows chassis and body telematics – along with 3rd Eye MobileVision camera feeds to be transported to the cloud via one cellular connection. This brings the idea of a “connected” truck front and center – and allows these features to be both monetized and audited, which is critical in a post-accident investigation – or providing credible documentation when applying for annual Federal Highway Tax payment recovery.

3rd Eye data modules, like Positive Service Verification, allow fleets to automatically collect snapshots and real time video of service stops, including those from customers who didn’t have their cans out to the curb in time, or showing waste containers blocked by parked cars. This feature can save haulers the added expense of sending out a second truck to handle these missed stops. Instead, savvy refuse haulers can charge an added fee for customers requesting a “redo”. Likewise, fleets running commercial front loaders can now capture images of dumpsters that are overloaded and upsell the customer on increased service intervals or a larger container. They can also use customizable “exception” features to capture site damage, contamination, or (as noted above) blocked container access – all which are recorded and available for immediate review and customer engagement. Access to this information means fleet owners have something more than “he said – she said” regarding route anomalies and can back it up with video-based evidence. A side benefit of having these consequence-based control systems in place, is that customer behavior changes – and the number of “route anomalies” will decrease over time.

Coachable MomentsThe liabilities present in any fleet operating heavy equipment on public roads is yet another sobering reality. Providing operators with the best teaching and coaching strategies is more than optimizing efficiency; it can be the difference between life and death. Literally. Equally critical is protecting fleets and operators from the dangers of other operators on the road – or conditions that impact the operator or the environment around the operator and the vehicle. 3rd Eye’s Gateway and two-way camera system provide for real-time video monitoring of both aspects; the operator and what the operator sees. Combine this with up to six additional cameras positioned around the vehicle, and fleet owners can have a 360° view of the vehicle’s environment.

Many fleets use this to conduct “virtual ride-alongs” with operators to monitor their route, provide coaching for unsafe behavior, and provide security if the vehicle is involved in an accident. In that situation, video can be viewed almost immediately by law enforcement to ascertain the conditions that led to the accident and assess liability based on empirical video evidence vs. allegations or claims by affected parties that may or may not have all of their facts straight.

Predictive Fleet Maintenance

With 3rd Eye Digital’s ability to capture and transmit body and chassis data to the cloud, fleet maintenance takes on a whole new meaning, because engine, hydraulic and electrical system health are able to be monitored in real time. Depending on what data subscription services are requested, hydraulic temperatures, pressures, cycle times, etc., can be monitored and tracked and then compared to baseline performance data. This information can then be used to assist in developing active maintenance schedules – that monitor and replace worn components before they fail, thus avoiding a truck down situation. This disruptive technology means that fleets can reduce the need for costly spare trucks as well as limiting the inventory of service parts it keeps on hand – and the added expense that goes with them. Besides reducing the need for valuable storage space, it’s also a lot easier on a fleet’s maintenance budget – as parts can be purchased based on imminent need instead of stocking multiple parts as an insurance policy to cover the “might fail” scenarios that most fleets currently anticipate.

The Journey Forward3rd Eye Digital product offerings are compatible with all major OEM class 6 – 8 chassis manufacturers and can be installed as an option with Western Star chassis at their factory. The installation is simple and involves adding the Hurricane Gateway™ in the cab and connecting this unit to the vehicle’s J-1939 backbone. Sensored body systems [hydraulic cylinders, electrical systems, pneumatic actuators, etc., can also be connected, with real-time data captured and transmitted to the cloud via Hurricane Gateway™. 3rd Eye MobileVision® cameras and radar can also transmit to the cloud. The entire suite of available data collection can then be downloaded automatically and integrated into any number of route monitoring and ERP solutions offered on the market.

The 3rd Eye Digital strategy – combined with meaningful operator coaching, forward-thinking fleet maintenance, and fleet safety personnel, can deliver a level of productivity, safety, and fleet efficiencies that will differentiate 3rd Eye subscribers from the competition almost immediately. As vehicles have evolved – so have the systems designed to monitor them. 3rd Eye is proud to be leading the safety and efficiency aspects of this maturing digital new world in the waste and recycling collection industry. It’s not just the Internet of Things. With the help of 3rd Eye Digital, It’s the Internet of Possible.

Download PDF Version of This White Paper.