JOB SAFETY ANALYSIS (JSA) KAIZEN PROGRAM

The Job Safety Analysis (JSA) Kaizen program is designed to prevent work-related injuries and illnesses by identifying, prioritizing, and eliminating EHS risks throughout Dover. This program helps to confirm that employees have the training, equipment, and supplies to do their jobs safely.

As part of the JSA Kaizen program, Dover’s corporate center has published two ergonomic assessment tools which can be used either in tandem with or independently from the JSA Kaizen tool. The ergonomic assessment tools are an important addition to the Dover EHS program because ergonomic injuries and illnesses account for the most prevalent incidents within our operating companies. These tools will facilitate the identification and mitigation of ergonomic risk factors within Dover, bringing us closer to achieving our vision of a Zero Harm Workplace.

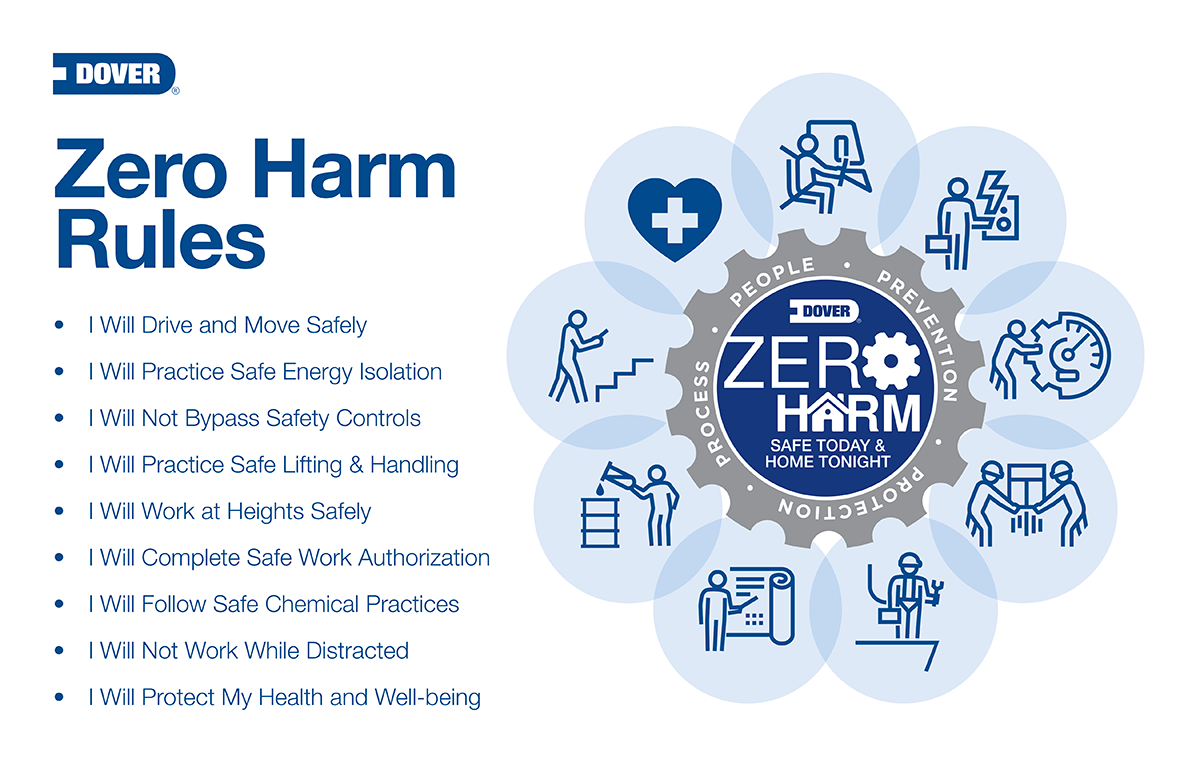

Zero Harm Program

Dover established the Zero Harm Program in support of its commitment to providing a Zero Harm Workplace. The program is based on a series of nine tenets that encourage employees to take accountability for their safety and wellbeing. The tenets are referred to as the Zero Harm Rules and are based on potential Dover Serious Injury and Fatality (SIF) precursors. Through the Zero Harm Program, Dover’s corporate center provides guidance and training, presented as Zero Harm Toolbox Talks, posters, and other visual aids. Additionally, we launched targeted campaigns to assist operating companies with mitigating and controlling Dover SIF precursors. These targeted campaigns are month-long events focused on reducing activities that pose a high risk to employee safety. Operating company facilities are expected to use the Zero Harm Program tools to support their Zero Harm journey.

0Dover Operational Excellence Model

To drive progress on safety across our operating companies, we use the 0DOVER Operational Excellence Model which, similar to a maturity model, establishes a minimum standard of expectations and processes across our operating companies and a common approach toward continuous improvement and achieving excellence in safety.